Servicing & Maintenance

Well maintained fire systems help save lives and propertyThrough our regular comprehensive servicing and maintenance services, our technicians aim to provide properly functioning fire equipment and systems. We service a huge range of fire protection systems for organisations large and small, we maintain all brands of various manufactured equipment.

Fire System Services provides you a fast and effective response. We have highly trained field staff, So when the heat is on, you can count on us to be there for you.

Fire System Services Service Technicians are on 24-hour standby; ready to undertake emergency repairs to your fire-protection systems and products. Our teams are equipped with self-contained vehicles and mobile technology that enables them to deal with most service problems on the spot.

Our technicians are trained to diagnose faults and reinstate systems as quickly as possible with the least amount of disruption. Our commitment to technical research and development enables our specialist technicians to keep up to date with a wide range of the latest technologies.

Our technicians are trained to diagnose faults and reinstate systems as quickly as possible with the least amount of disruption. Our commitment to technical research and development enables our specialist technicians to keep up to date with a wide range of the latest technologies.

Maintenance Capabilities

We offer a range of customized Servicing and Maintenance Services

Fire Alarm & Detection System Inspection & Maintenance

An annual inspection and test of a percentage of smoke & thermal detectors is also required. This ascertains that the detection and early warning systems are functional.

Once installed a Fire Alarm and Evacuation System should be regularly maintained. The minimum maintenance requirements are:

- Monthly test of the fire panel and evacuation tones

- Annual test of a sample of fire detectors and operation of all ancillary devices

The maintenance of a fire alarm and evacuation system should only be undertaken by a competent person. Stars Fire & Safety employs trained personnel in the testing of fire alarm and evacuation systems who are well versed in all the mechanics of such a complex system.

Fire Extinguisher, Fire Blanket Inspection & Maintenance

Stars Fire & Safety can relieve the burden by providing a risk assessment service to determine your fire protection requirements, and once this is completed advise on the placement and types of fire extinguishers required to ensure compliance with relevant standards.

Stars Fire & Safety can offer a comprehensive servicing package, which means you can be confident that your fire extinguishers are maintained every six months. Our trained technicians, who are easily identifiable by their uniforms, will regularly visit your premises to ensure that your fire equipment is in proper working order and appropriate to your level of fire risk. In addition you may rest assure that when the cylinders are due for their yearly pressure test, they will be tested back in our licensed facility.

Stars Fire & Safety supplies high quality, easy to use fire extinguishers manufactured to the Standard.

Regular Scheduled Program

As part of a regularly scheduled program, our experienced technicians will:

- Test all equipment and systems in accordance with the Standards

- Repair and replace components where required.

- Record all the work performed in your site fire equipment log book / register or on a certificate of inspection.

Quick checklist for fire extinguishers

- Fire extinguishers must be clearly visible & signage should indicate their location.

- They must be easily accessible

- The correct type of extinguisher should be located near a fire hazard

Fire Hose Reel Inspection & Maintenance

Fire hose reels should be located within 4 meters of an exit from the building and be no further than 40 meters from any part of the building.

Once installed fire hose reels should be regularly maintained. The minimum maintenance requirements as documented

- Bi-yearly test

- Annual test where the hose is fully unwound and water flow readings are taken.

Our field team also assess your fire hose reel requirements by conducting periodical inspections & annual flow tests in accordance to Standards to prove they function as required.

Fire Hydrant Booster, Fire Hydrant Testing & Maintenance

Stars Fire & Safety can undertake a review of your site and advise you if you are likely to require fire hydrants and where they should be located.

Once installed fire hydrants should be regularly maintained. The minimum maintenance requirements as documented are:

- Six monthly inspections for damage and that the hydrant is clear of obstructions

- Test for the presence of water

- Annual test for the presence of water and conduct water flow test of system

- Overhaul and test to ensure that there is adequate water flow for firefighting purposes

Stars Fire & Safety offers a range of parts and services. We provide competitive prices in the line of six monthly, yearly and five yearly flow testing & servicing of your hydrants & hydrant booster systems. This is when the booster system is required to be overhauled and the most hydraulically disadvantaged fire hydrants have their water supply readings taken.

Fire Sprinkler System Inspection & Maintenance

Stars Fire & Safety can undertake a review of your site and advise you if you are likely to require a fire sprinkler system and whether the layout of your existing fire sprinkler system meets the current Standards. The final determination of the type and layout of a fire sprinkler system is undertaken by a Building Surveyor.

Once installed a Fire Sprinkler System should be regularly maintained. The minimum maintenance requirements as documented are:

- Monthly test of ensure that each sprinkler system will go into alarm

- Six monthly test of all ancillary equipment

- Annual test to ensure that there is adequate water supply for the fire sprinkler system

- Five yearly test full overhaul for the fire sprinkler system

Whether it’s about protecting your residential building, warehouse or office tower, sprinklers are both fire detection and control systems rolled into one. Thereby the most effective fire suppression system available.

Stars Fire & Safety will assess your property’s unique needs, providing detailed designs suited to your building and local safety standards requirements.

Looking at the building’s functionality, occupancy, spatial area and level of fire risk, Stars Fire & Safety engineers will tailor your sprinkler system to your property’s precise needs.

If it is maintenance that you require, Stars Fire & Safety runs and operates a fire sprinkler service division, ranging from monthly inspections through to annual sprinkler testing including annular flow testing, certification of systems and wall wetting systems, to five yearly system overhauls.

Fire Safety Audits

These Audits are extremely helpful if you require a detailed report of the condition of your property.

Audits including the following:

- Egress

- Exit & emergency Lighting

- Above Ceiling Compartmentation

- Fire Safety Equipment

- Fire and Smoke Doors

- Fire and Smoke detection layouts

- Fire Proofing and Sealing

- Inspection relating to paths of travel, exit lighting, build up of rubbish creating a fire hazard

- Fire Proofing relating of fire collars, fire caulking

Firefighting Foam Testing Services

Foam Tests Expansion Ratio: The foam testing regime establishes the quality of the foam blanket produced from the sample provided. The foam is checked for its expansion ratio. The test is designed to mimic the action of the foam blanket.

pH Tests: The pH is checked to confirm the efficacy of the concentrate.

Density Determination: The density or specific gravity of the foam is checked. This can confirm the type of foam, synthetic or protein, and any potential contamination problems that may be present.

Surface Tension Tests: The surface is measured to confirm the foam integrity. A low surface tension indicates the product has the ability to wet out materials which is a key feature of fire fighting foams.

Sediment Checks: The foam is checked for sediment. This analysis will also test the integrity of the storage container.

Refractive Index Test: Stars Fire & Safety will complete Refractive Index analysis on foam-water solutions. This is suitable for premix solution and also foam systems testing.

Foam Monitoring can be carried out by Stars Fire & Safety for customers “peace of mind”.

Vehicle Fire Suppression Systems

We can review your vehicle fire suppression systems to ensure their continued effectiveness. And we can help conduct a full risk assessment to make sure your systems meet your requirements.

Stars Fire & Safety offers full installation service. We are able to service and maintain dry chemical powder, Foam spray systems and vaporizing liquid system.

Regardless of the manufacturer, we can also service and repair all systems and provide call outs and routine maintenance. With our workshop capabilities, if the cylinders are out of date we are able to hydrostatically test, rebuild and recommission the cylinders.

Kitchen Hoods, Fume Hoods and Exhaust Hoods

We undertake designing, installation, servicing and maintenance of Industrial and Commercial Hood and Exhaust Systems.

Our capabilities:

- Stainless Hoods

- Exhaust and Supply Duct work

- Exhaust fan

- Make-Up air

- Stainless Steel Wall Panels

For commercial kitchen and restaurant construction which includes kitchen hood, make up air unit HVAC, gas, electrical, framing, drywalling, taping, painting, plumbing and flooring installation. Stars Electro Mechanical will design, built, test, repair, service and maintain all your exhaust hood needs.

Associated Services

Cylinder Liquid Level Testing

Our ultrasonic liquid level testing is designed to assist the fire technician to check various gas traffics in cylinders ranging from CO2, FM200, NAF S III, and other replacement liquids of gaseous extinguishers quickly and simply without having to weigh the cylinders.

Hence reducing the costs to the owners of having to bring in expensive lifting and weighting equipment. Testing can be achieved without removing the cylinders from their manifold, saving considerable time in testing and reducing risk to the operators.

Cylinder Pressure Testing

The hydrostatic pressure testing rig is designed to hydrostatically test cylinders and other devices, and is able of reading the volumetric expansion of the cylinder.

Air Testing Apparatus

The air testing rig has been designed to test with pure breathable air as the test medium. Occasionally we are asked to proof test or leak test devices with a medium that contains no fluids or moisture.

Low Pressure Testing Pumps

Fire System Services has several low pressure test pumps. These low pressure test pumps are fully portable and versatile, making them ideal for hydrostatically testing cylinders both in the workshop and in the field.

Custom Testing Services

Apart from cylinders, the station is called upon to hydrostatically test & certify various items used in custom designs and prototype devices.

Electrical Related Services

Exit and Emergency Lighting Inspection and Maintenance

This test certifies that all the exit & emergency lights are functional and batteries sustain their charge for 90 minutes during a power blackout or building fire. We offer a full backup service where the light fittings can be tested, maintained and repaired in the field, or returned to our workshop for bench testing.

We also supply a full range of Nickle Cadmium battery packs and Sealed Lead Acid batteries.

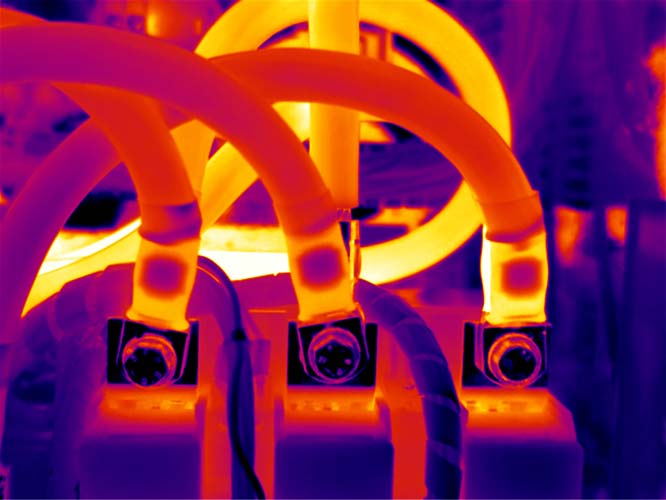

Thermal Imaging & Electrical Safety

Home and Office Problems with power boards can arise from:

- Overloading the power board.

- Dust build up in the unused points.

- Power leads becoming dislodged over time, particularly under a desk where they are knock by feet.

- Poor placement of power cables and extensions chords leading to the power board

- In adequate ventilation or the power board preventing “normal” dissipation heat generation.

- Limited or no understanding of the amount of power being drawn by different appliances.

- Heavy Plug-in transformers that will “over balance” and partially unplug, resulting in over heating from poor connections.

Stars Fire & Safety offers a scanning program that can detect potential fire hazards on low voltage switchboards.

The new thermal imaging program uses thermo graphic camera technology to detect hotspots on low voltage switchboard equipment before they develop into faults, fires or explosions.

Our Expertise

Stars Fire & Safety undertakes the following types of Servicing and Maintenance.Fire Safety

Fire Alarm & Detection Systems Inspection and Maintenance

Fire Extinguishers Inspection and Maintenance

Fire Hose Reels Inspection and Maintenance

Fire Hydrant and Booster Systems Inspection and Maintenance

Fire Sprinkler Systems Inspection and Maintenance

Fire Safety Audits

Firefighting Foam Testing Services

Vehicle Fire Suppression Systems

Associated Services

Cylinder Liquid Level Testing

Cylinder Pressure Testing

Electrical

Exit and Emergency Lighting Inspection and Maintenance

Thermal Imaging & Electrical Safety